RB

COMBIPILE

The RBL Combipile offers a robust, versatile, cost-effective foundation solution for overcoming difficult driving conditions. In scenarios where potential damage to a precast pile is of concern, the Combipile can be employed as a cost-effective alternative to a driven steel tubular pile.

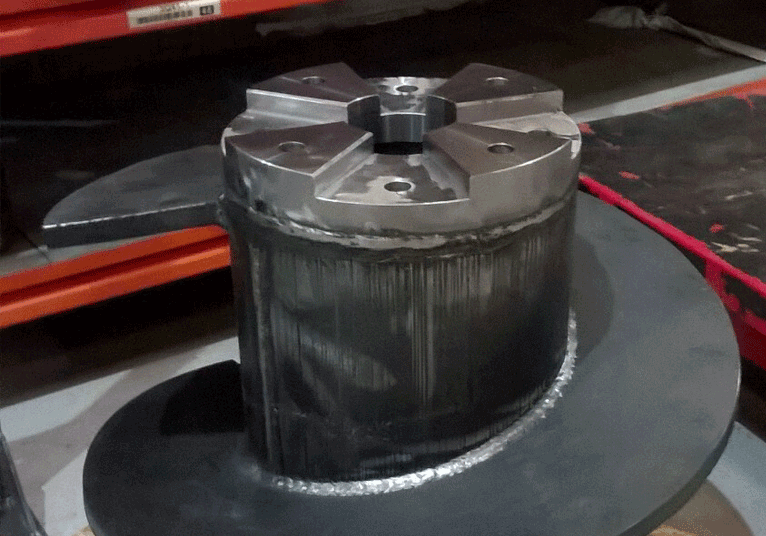

This innovative approach utilises a steel starter section, repurposed from the oil and gas industry, with precast elements to offer a durable and sustainable product. With the precast elements being designed and manufactured in-house in segmental lengths, waste on site is minimised.

In essence, the RBL Combipile harnesses the benefits of both Driven Tubular Steel Piles and Driven Precast Concrete Piles to provide a sustainable and cost-effective piling solution.

WHAT THEY’RE USED FOR

Similar to our driven precast concrete piles, the RBL Combipile has a lot to offer as a reliable and widely applicable solution. This product can be employed over a range of different sectors from housing and commercial developments to industrial and infrastructure projects. They are perfectly suited to address challenging ground conditions, for example where dense or potentially obstructive made ground is present and may hinder precast pile installation.

The RBL Combipile is an efficient displacement solution that does not generate soil arisings during installation with the only waste being generated from pile cropping works, which is reduced as segmental lengths are used and tailored to each project. This reduces the volume of waste products to be disposed of, with a subsequent reduction in traffic movements and cost.

The RBL Combipile can be designed to cater to a range of different types of loadings and come in a variety of section sites to allow for the most suitable selection of product size during the design stage. This pile type is commonly used to support pile caps, beams, and slabs and is a perfect pairing for our Precast Concrete Beaming System, RBeam.

THE PROCESS

With both the steel starter section and follow-on precast product being available in varying segmental lengths, the RBL Combipile is an efficient foundation solution. The steel starter section is pitched and driven, and subsequent precast pile sections are added to suit the required depths and minimise material wastage. Pile installation progresses to a design length or refusal criteria to suit the ground conditions and loading requirements of the individual scheme.

This pile type offers a quick and efficient installation process with no spoil arisings generated through the installation process. Furthermore, immediately following pile installation the piles are ready for follow-on trades. The precast section of the pile is easily cropped by follow-on trades and tied into the substructure.

RBL Combipiles are installed using RBL’s purpose-built remotely operated ‘quiet-hammer’ rigs, which are designed to minimise noise and disturbance to surrounding areas. Furthermore, RBL rigs are designed in-house to achieve significantly lower bearing pressures in comparison to other commercially available rigs, which offers the potential for a reduction in piling platform thickness.

WHY USE RB Combipile?

- Environmentally friendly

- Alternative to precast providing a greater resistance during driving to overcome obstructions

- Cost-effective

- Quiet installation

- Zero spoil

- Purpose built rigs

ROGER BULLIVANT

QUALITY CONTROL

We successfully deliver projects to the highest standard, safely, on time, within budget, and with care for the environment and communities. Clients choose RB time and time again thanks to our proven track record.

All products are manufactured to BSEN, ISO, and CE accreditation. We are committed to ensuring we continuously deliver high quality, robust service, and product to our clients. At RB we continuously review and access where we can further improve.

We are proud to be recognised and awarded the RoSPA gold award for the sixth year running for the exceptionally high standards towards the health and safety of our employees.