CHD

PILES

Continuous Helical Displacement (CHD) piles offer a highly efficient displacement cast-in-situ piling solution producing nominal arisings, in comparison to CFA piles. This innovative technique not only minimises waste leaving the site but also offers the advantages of virtually vibration and noise-free installation.

CHD piles have gained popularity as an environmentally conscious and efficient foundation solution, showcasing their adaptability in addressing both construction needs and sustainability considerations.

WHAT THEY’RE USED FOR

CHD piles provide a broad spectrum of applications across diverse sectors and construction projects. Predominantly favoured within the residential and commercial sectors, this innovative technique offers an efficient and adaptable solution for foundation needs. The versatility of CHD piles extends to different types of soils, making them suitable for projects dealing with loose to medium dense, becoming dense sands & gravels, and cohesive soils ranging from soft to stiff silts and clays.

Whether providing a foundation solution for residential structures, supporting the infrastructural demands of commercial buildings, or offering stability in challenging soil conditions, CHD piles prove to be a reliable and versatile choice. The applicability of CHD piles across a range of sectors and ground conditions underscores their effectiveness as a foundation solution, providing flexibility and reliability in meeting the diverse construction needs of residential and commercial projects alike.

THE PROCESS

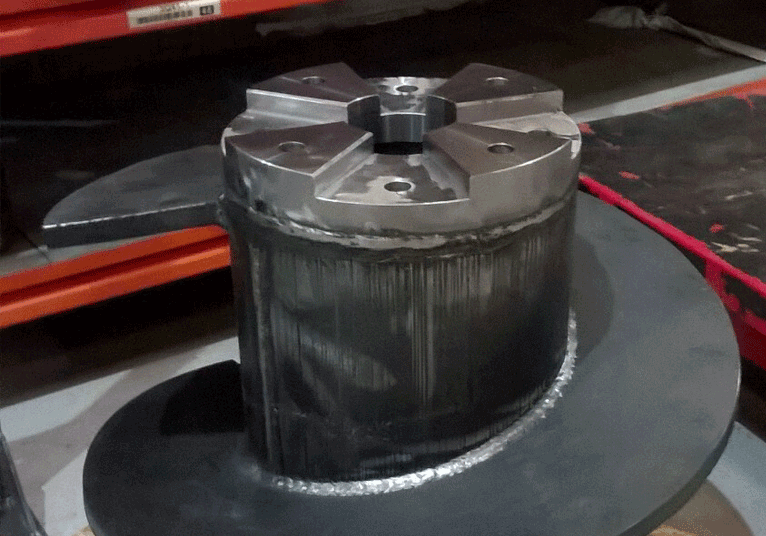

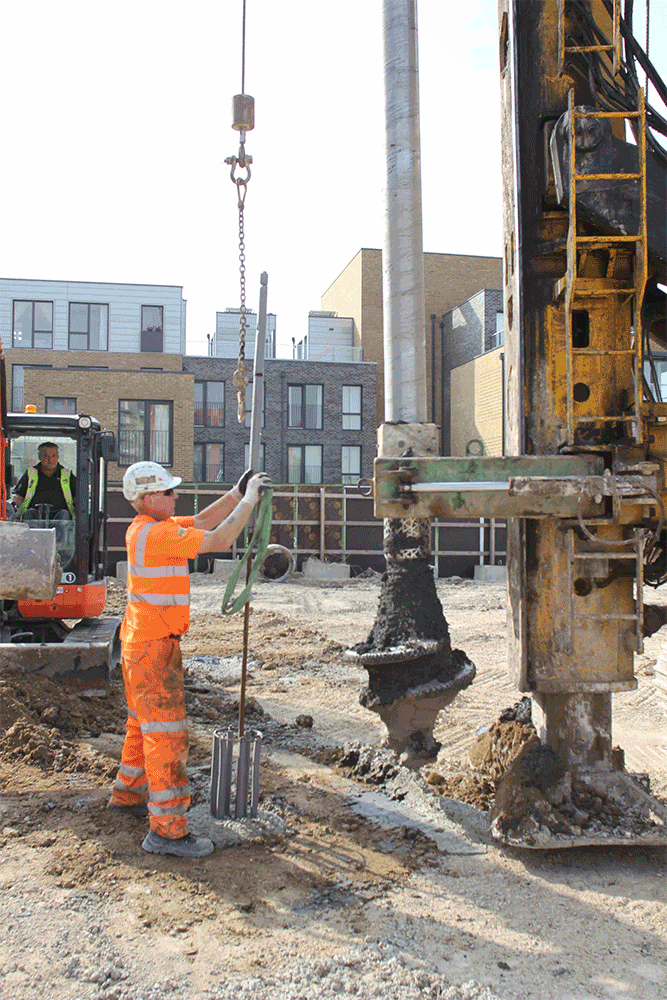

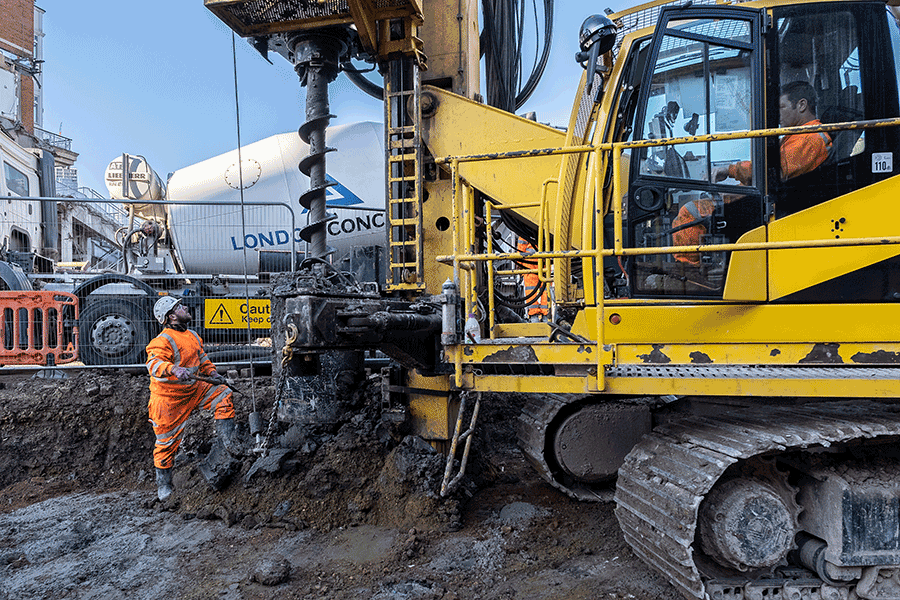

The installation of our CHD piles is automated, controlled, and recorded using computerised instrumentation. The pile is formed using a highly efficient multi-flight bullet-ended shaft, driven by a torque rotary head, enabling penetration of the underlying strata with only nominal arisings being generated. Once drilled to calculated or proven depth, concrete is pumped under pressure down the hollow shaft to the boring head and out of the tip while the shaft is reverse rotated and withdrawn from the bore. This forms the characteristic shape of an enhancing single continuous flight rotating around a central and continuous core. Reinforcement in the form of a cage and additional bars as necessary are introduced into the bore upon completion of the concreting operations. Surface heave and waste are cleared from the formation to complete pile construction.

WHY USE CHD Piles?

Alternative to CFA piles

Cost effective as it reduces minimal waste

Ideal for contaminated sites

Can be used for cohesive and non-cohesive soils

Improved soil strength

Improved pile capacity and load transfer

EXAMPLE CHD PILING PROJECTS

ROGER BULLIVANT

QUALITY CONTROL

We successfully deliver projects to the highest standard, safely, on time, within budget, and with care for the environment and communities. Clients choose RB time and time again thanks to our proven track record.

All products are manufactured to BSEN, ISO, and CE accreditation. We are committed to ensuring we continuously deliver high quality, robust service, and product to our clients. At RB we continuously review and access where we can further improve.

We are proud to be recognised and awarded the RoSPA gold award for the sixth year running for the exceptionally high standards towards the health and safety of our employees.