HELICAL DISPLACEMENT

INCLUSIONS

Helical Displacement Inclusions (HDIs) serve as a robust method of ground improvement on projects characterised by low-strength soils, high structural loading, or strict settlement criteria.

The inclusions act as a reinforcing element within the soil profile which functions through a composite of a load transfer platform (LTP), enhancement of soils, and frictional bearing to support the structure. The load redistribution occurs as an arching effect between the inclusions and the immediate surrounding soils. The load applied to the HDI is characterised as a balance of positive and negative skin frictions along the length of the inclusion as well as partial end-bearing capacity within more competent underlying soils.

This ground improvement technique employs eco-grout or low cement concrete, offering a more environmentally friendly alternative to conventional piling. The displacement auger method of installation offers both rapid deployment and minimal spoil or arisings. Unlike traditional methods that may require reinforcement, extensive excavation, cropping, and capping, HDIs can be installed to a pre-determined depth with any manipulation occurring prior to curing. This provides a shorter duration than traditional augered piling with fewer post-installation activities. The displacement auger method also generates minimal noise and vibration, making it particularly suitable for sensitive sites.

WHAT THEY’RE USED FOR

HDIs offer a robust development platform for the construction of traditional shallow foundations, providing a stable and reliable base for a diverse range of structures. This method facilitates the construction of foundations directly atop the LTP and subsequent reinforced soil, eliminating the need for extensive underbuilt or heavily reinforced foundation systems.

HDIs' adaptability and effectiveness render them an ideal solution for projects where traditional foundation methods may be impractical or costly. The versatility of HDIs extends across various sectors, making them a preferred choice for large-scale projects. They are well-suited for supporting low to mid-rise construction (such as residential, commercial, retail, and healthcare facilities), heavily loaded buildings, and industrial works as well as infrastructure and services. The applicability of HDIs across a range of sectors and soil types underscores their effectiveness as a foundation solution, providing flexibility and reliability in meeting the needs of any given project.

THE PROCESS

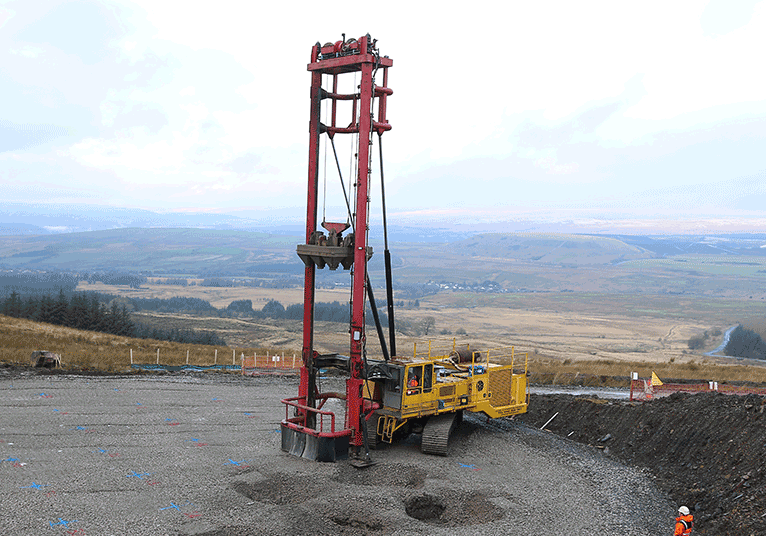

The process of HDIs introduces a reinforcing element into the soil mass through the installation of rigid concrete columns or ‘inclusions’, typically between 300 - 450mm in diameter. This is achieved using a displacement auger, which penetrates through the working platform and underlying soils to a predetermined design depth. The helical tooling is then reversed during extraction, whilst concrete is pumped under pressure into the resultant helical-shaped void, forming the inclusion within the soil. Through the introduction of multiple inclusions at predetermined depths and centers, a blanket coverage of the structural footprint is provided.

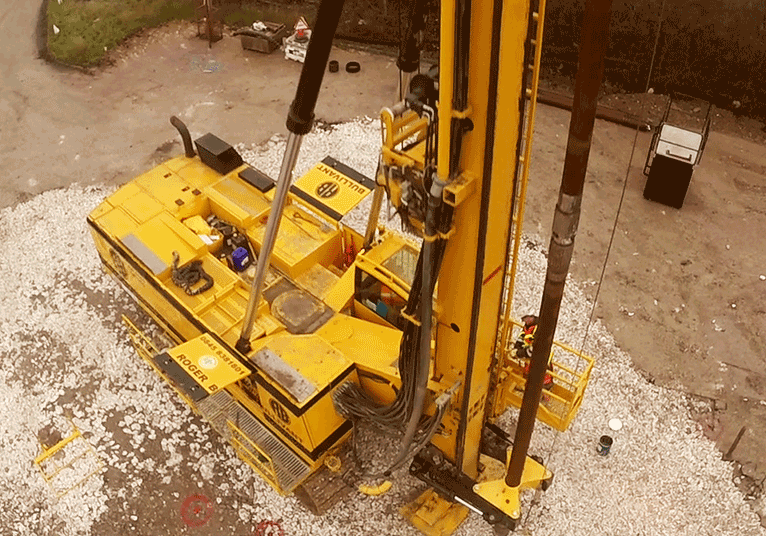

The entire operation is monitored and logged by the purpose-built HDI Rigs, equipped with comprehensive instrumentation. This ensures precision and accuracy throughout the installation process as well as real-time data recall and monitoring of the process.

Any surface heaves and waste is cleared from the formation to complete HDI construction. Once the concrete has sufficiently cured and the formation level is confirmed, the aggregate LTP is formed atop the HDIs to a given thickness, and testing is undertaken to ensure both elements function within the specified limits. This is serviced by way of short-duration plate load and longer-duration zone loading or kentledge tests on the composite solution. From this point, the contractor then proceeds to form traditional foundations atop the LTP to permit the superstructure.

WHY USE Helical Displacement Inclusions?

- Fast installation

- Vibration free

- Increase bearing capacity of weak soils, even for high loads

- Columns are cast in-situ, using high torque displacement tool

- Adequately designed load transfer structure ensures even loading of the inclusions which act in composite with the soil

- Suitable for all sectors and loading structures

ROGER BULLIVANT

QUALITY CONTROL

We successfully deliver projects to the highest standard, safely, on time, within budget, and with care for the environment and communities. Clients choose RB time and time again thanks to our proven track record.

All products are manufactured to BSEN, ISO, and CE accreditation. We are committed to ensuring we continuously deliver high quality, robust service, and product to our clients. At RB we continuously review and access where we can further improve.

We are proud to be recognised and awarded the RoSPA gold award for the sixth year running for the exceptionally high standards towards the health and safety of our employees.