RBL's precast ground beam system, known as RBeam, has been developed in-house, and is manufactured to exacting standards offering a superior alternative to traditional in-situ ground beams. Unlike conventional methods, RBeam is a non-weather dependant solution, ensuring consistent performance regardless of environmental factors.

This reliability not only enhances installation efficiency but also minimises material waste, contributing to a more sustainable construction process. Moreover, RBeam significantly reduces carbon emissions compared to trench fill foundations, aligning with contemporary environmental goals. Its modular design allows for individual beams to be adjusted, providing unparalleled flexibility in accommodating diverse and complex plot layouts and drainage needs. Overall, RBL's RBeam system epitomises innovation in foundation solutions, combining efficiency, sustainability, and adaptability to meet the demands of modern construction projects.

WHAT THEY’RE USED FOR

RBeam's versatility extends to both residential and commercial building ventures, making it a versatile solution for various construction projects. Classified within the Modern Method of Construction (MMC) Category 3 – Pre-manufactured Components, as outlined by the Department for Levelling Up, Housing and Communities framework, RBeam is recognised for its role as a non-systemised primary structure. This distinction underscores its importance as a key component of modern construction practices, particularly in the realm of off-site manufacturing.

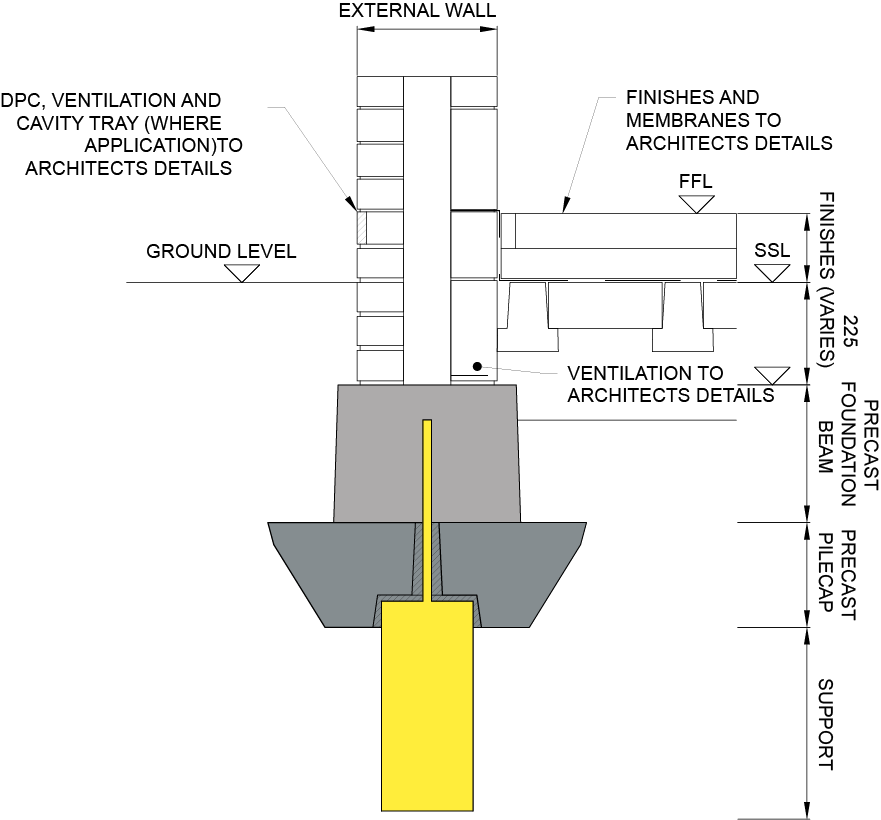

Compatible with a broad spectrum of piled foundation techniques, RBeam adapts seamlessly to diverse soil compositions and ground conditions, including those susceptible to heave. Its adaptability enhances construction flexibility and mitigates the risks associated with challenging terrains.

The off-site manufacturing process of RBeam enables expedited project timelines by enhancing productivity, quality, and safety standards. Whether employed in modular or traditional construction methodologies, RBeam facilitates accelerated build programs without compromising on structural integrity or performance. As a result, it contributes to elevating the pre-manufactured value (PMV) of a project, emphasising efficiency, sustainability and innovation in contemporary construction practices.

THE PROCESS

The comprehensive RBeam system encompasses five types of beams, each available in a variety of standard lengths. This extensive range empowers our in-house design team to tailor highly efficient foundation solutions to meet the unique requirements of virtually any project. By offering a diverse selection of beams, we ensure flexibility and adaptability, enabling precise customisation to match specific site conditions and structural demands.

Moreover, the RBeam system seamlessly integrates with all our piling techniques, providing a cohesive approach to foundation construction. This synergy allows for optimised coordination and alignment between pile installation and beam placement, ensuring seamless structural integrity throughout the foundation assembly process.

As part of our commitment to delivering innovative solutions, we offer the RBeam system as a comprehensive procurement package. This holistic approach encompasses every stage of the project lifecycle, from initial design and detailing to setting out, manufacturing, and installation of both piles and beams. By consolidating these services into a single offering, we streamline project management, enhance communication and minimise potential points of friction, ultimately delivering superior outcomes for our clients.

WHY USE RBeam?

- Package solution also include setting out; design, manufacture and installation

- Factory quality and safety

- Non weather dependant

- Produces a flexible modular foundation

- Improved cost certainty

- Reduced waste and C02 emissions

- Ideal for both traditional and modern methods of construction

- Minimum site preparation required

- Off-site manufactured, ready for immediate dispatch

EXAMPLE RBEAM PROJECTS

ROGER BULLIVANT

QUALITY CONTROL

We successfully deliver projects to the highest standard, safely, on time, within budget, and with care for the environment and communities. Clients choose RB time and time again thanks to our proven track record.

All products are manufactured to BSEN, ISO, and CE accreditation. We are committed to ensuring we continuously deliver high quality, robust service, and product to our clients. At RB we continuously review and access where we can further improve.

We are proud to be recognised and awarded the RoSPA gold award for the sixth year running for the exceptionally high standards towards the health and safety of our employees.

Other Piling Methods

Sorry, we couldn't find any posts. Please try a different search.