PROJECT BRIEF

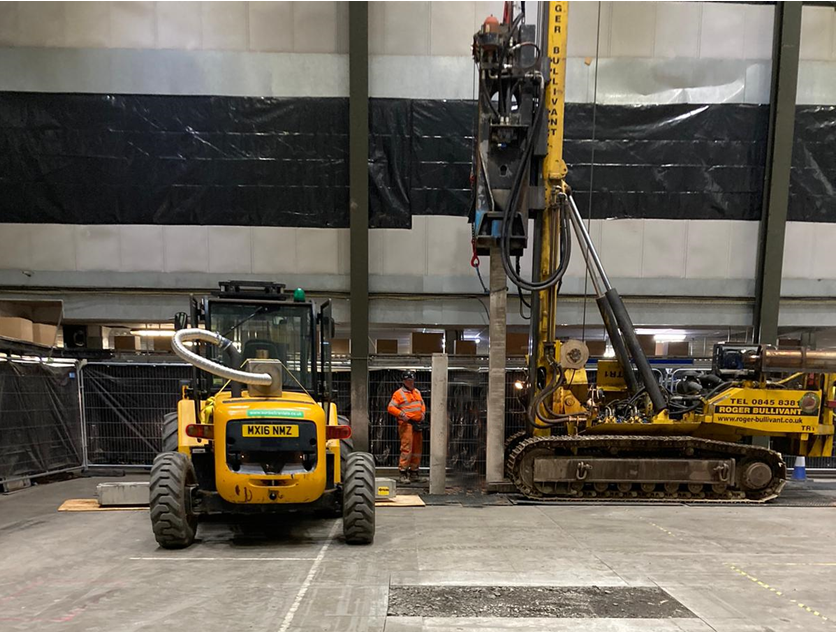

Chartered Mill Ltd appointed Roger Bullivant Limited to install Precast Concrete Piled foundations to support columns for a new four-tier mezzanine floor in an existing warehouse. The objective was to strengthen existing foundations within the warehouse.

Using their extensive knowledge of the Avonmouth area, the Southern team presented a proposal using the RBL Driven Precast Concrete Piling System, which was determined to be appropriate for the project’s specific site conditions and requirements, resulting in a successful outcome.

KEY ISSUES

- Following a thorough site investigation, it was discovered that the strata consisted of around 3.60m of man-made ground located directly above Tidal Flat Deposits. These deposits, in turn, were situated underneath the anticipated solid geology of the Mercia Mudstone Group, which was found at a depth of 16.0m.

The client instructed RB to install 70 load-bearing piles with a maximum load capacity of 505kN. - The piling project was scheduled to take place during night-time hours.

- The site presented a significant challenge due to its limited access, with a headroom clearance of only 12.0m.

- The small entrance, measuring just 3.5m by 5.0m, posed an additional obstacle in transporting the 4.0m pile segments into the warehouse.

- Another challenge that arose during the project was poor ventilation, exacerbated by the operation of rigs and forklifts, with the release of exhaust gases, creating a high-risk environment in the confined and enclosed work area.

- The piling team also faced difficulties due to the out-of-hours working programme.

SOLUTION

- The team utilised specialised equipment and techniques to work effectively within the limited headroom. Specifically, the team employed the TR1 rig from RB’s extensive mini piling fleet, which boasts a headroom clearance of 12.0m. These features allowed the team to successfully navigate the limited headroom and execute the piling operations efficiently.

- DPF-HD90 filters were installed on the forklift and TR1 rig. The filters reduced harmful emissions, safeguarding the operation team from hazardous pollutants, whilst fully complying with Health and Safety Regulations.

- Effective planning was crucial to the success of the piling project conducted at night within an existing warehouse. This entailed a thorough evaluation of site conditions, prioritising worker safety, and devising a detailed schedule. Through clear communication and by transporting all pile segments during the daytime, the project was safely and efficiently completed.

- Despite the challenges posed by the restricted access and working headroom, this project was completed successfully through careful planning and execution. The project exemplifies the significance of thorough planning, effective communication, and collaborative efforts in accomplishing project objectives.