CHAD

PILES

Continuous Helical Auger Displacement (CHAD) piles offer a suitable alternative to conventional CFA piles, introducing an innovative iteration of RBL’s proprietary CHD pile. The distinguishing feature of CHAD piles lies in their enhanced ability to overcome challenging ground conditions by using a multifunctional boring head.

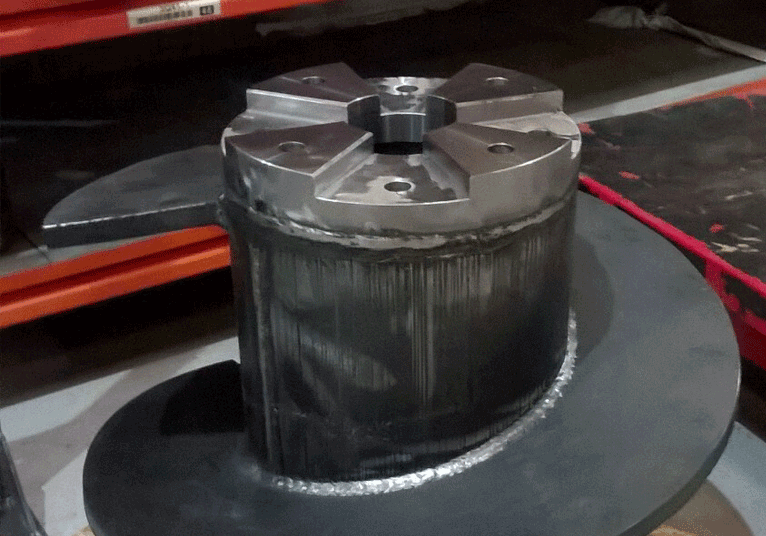

This consists of an outer casing with a 450/750mm diameter bullet which mirrors the CHD boring head profile. The outer casing houses an internal 350mm diameter CFA Auger which can be advanced ahead of the casing to release ground pressure through over consolidated layers.

What sets RBL's CHAD solution apart is the reduction of the amount of spoil generated during the piling process when compared with equivalent diameter CFA piles. This not only streamlines the construction process but also aligns with sustainable practices by minimising the environmental impact associated with excessive excavation.

WHAT THEY’RE USED FOR

CHAD piles have widespread applications predominantly in the commercial and industrial sectors, offering a reliable solution for partial displacement piling. Well-suited for structures with medium to high loads, CHAD piles showcase their versatility in a range of soil types.

The versatility of CHAD piles extends to different types of soils, making them suitable for projects with loose to medium dense, becoming dense sands & gravels, and cohesive soils ranging from soft to stiff silts and clays. CHAD’s adaptability and effectiveness offer an ideal solution where the density of soil strata may preclude the use of our proprietary CHD pile.

The distinguishing feature of CHAD piles lies in their ability to reduce the amount of spoil generated during the installation process. Due to the displacement capabilities of our CHAD pile, RBL is able to install shorter piles in comparison to equivalent CFA piles. This not only reduces the volume of spoil to be removed off-site, it also offers a reduction in concrete volumes as a result of shorter piles being installed which leads to a reduction in overall traffic movements on site.

This versatility positions CHAD piles as a preferred choice across different construction scenarios, demonstrating their capability to navigate through various soil conditions while efficiently supporting structures with varying load requirements. Whether in residential projects, commercial developments, or industrial facilities, CHAD piles emerge as a dependable and adaptable foundation solution.

THE PROCESS

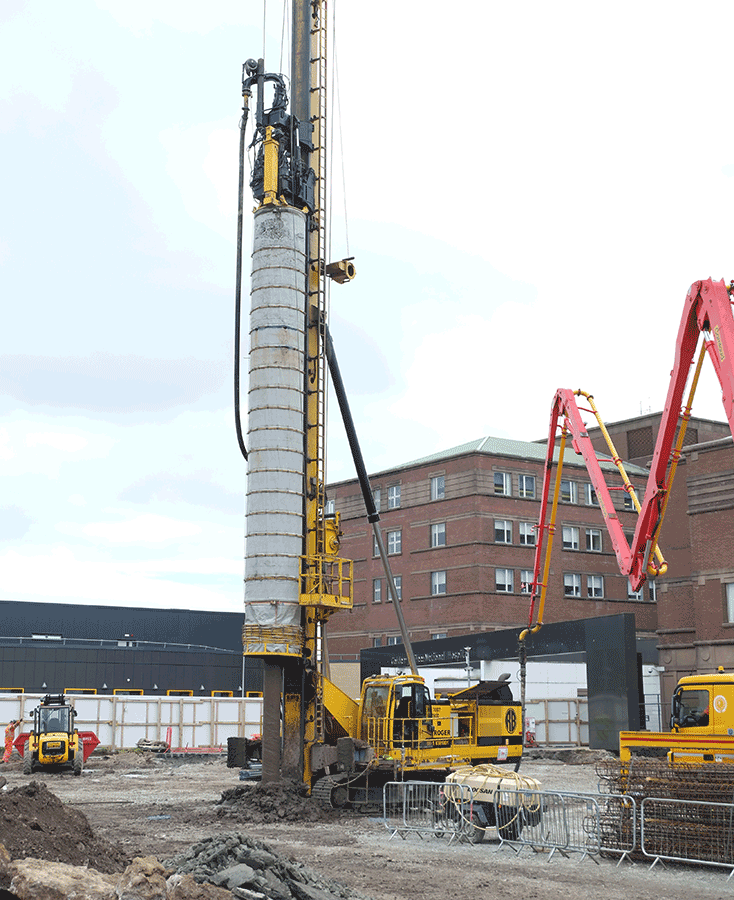

CHAD piles are constructed adopting a carefully controlled process initiated by drilling the CHAD casing to the specified design depth. Within the CHAD casing, a string of hollow stem augers extract soil from the ground. During the formation of the CHAD pile, spoil arising is initially stored within the drive casing and may overflow through the hole in the top of the casing. Any overflow of arisings is contained within the apron surrounding the casing.

Once drilled to a calculated or proven depth, concrete is pumped under pressure down the hollow shaft of the auger, whilst the casing is reverse rotated and withdrawn from the bore. This forms the characteristic profile of an enhancing single continuous flight rotating around a central and continuous core. On completion of the concreting phase of the pile, the CHAD rig manoeuvres to the side and deposits any spoil stored in the casing which is then cleared from the platform.

Reinforcement in the form of a cage and additional bars as necessary are introduced into the bore upon completion of the concreting operations.

This process completes the formation of the CHAD pile, creating a robust foundation that adheres to the project's design requirements. The combination of precision drilling, reinforcement, and concrete infusion results in a reliable and structurally sound pile, making CHAD piles a valuable choice in the realm of foundation construction.

WHY USE CHAD Piles?

- Reduced spoil compared to CFA piles

- Able to penetrate denser strata than regular CHD piles

- Improves soil strength

- Can be used for all foundation applications where bearing piles are required for structures

- Virtually vibration-free

- Ideal for urban or sensitive locations

- Quick installation benefitting contract programming

ROGER BULLIVANT

QUALITY CONTROL

We successfully deliver projects to the highest standard, safely, on time, within budget, and with care for the environment and communities. Clients choose RB time and time again thanks to our proven track record.

All products are manufactured to BSEN, ISO, and CE accreditation. We are committed to ensuring we continuously deliver high quality, robust service, and product to our clients. At RB we continuously review and access where we can further improve.

We are proud to be recognised and awarded the RoSPA gold award for the sixth year running for the exceptionally high standards towards the health and safety of our employees.