VIBRO STONE

COLUMNS

Vibro Stone Columns serve as a rapid and economical foundation solution, particularly in areas with weak or unstable soil conditions. By targeting specific areas, they effectively increase soil density and strength, improving settlement characteristics and overall stability.

This method offers a cost-effective and sustainable alternative to traditional deep foundation piling, minimising both financial and environmental impacts. Additionally, unlike some other methods, Vibro Stone Columns do not generate any spoil, further reducing project complexities, environmental concerns and costs.

WHAT THEY’RE USED FOR

Vibro Stone Columns offer versatile applications across various sectors, including residential, commercial, industrial, and infrastructure projects. Their adaptability makes them a preferred choice for a wide range of soil conditions, including weak natural soils and made ground. Additionally, they are particularly well-suited for addressing challenges posed by contaminated ground, as they produce no spoil, minimising the risk of spreading contaminants.

This method is commonly employed to enhance the load-bearing capacity of the soil, mitigate settlement issues, and expedite the consolidation process. By effectively compacting and reinforcing the soil, Vibro Stone Columns provide a stable foundation for structures of many sizes and types. Whether supporting residential developments, industrial facilities, commercial complexes, or critical infrastructure projects, Vibro Stone Columns offer a reliable and efficient solution for improving soil conditions and ensuring long-term structural integrity.

THE PROCESS

TOP FEED METHOD

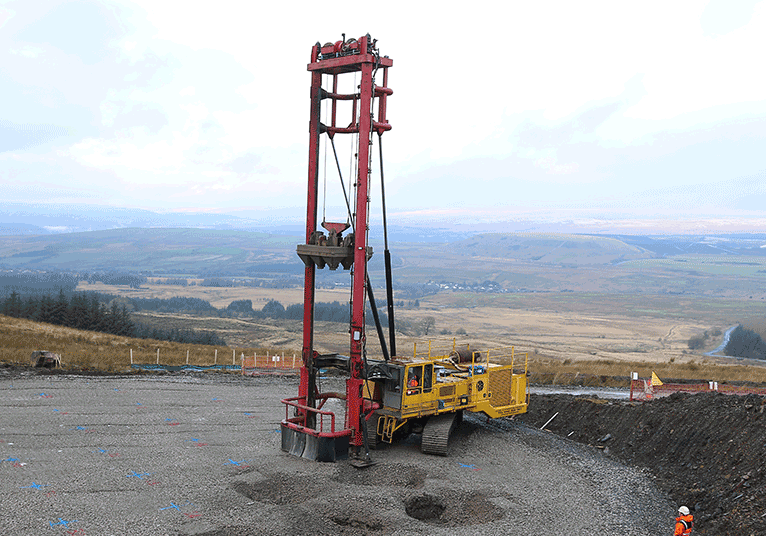

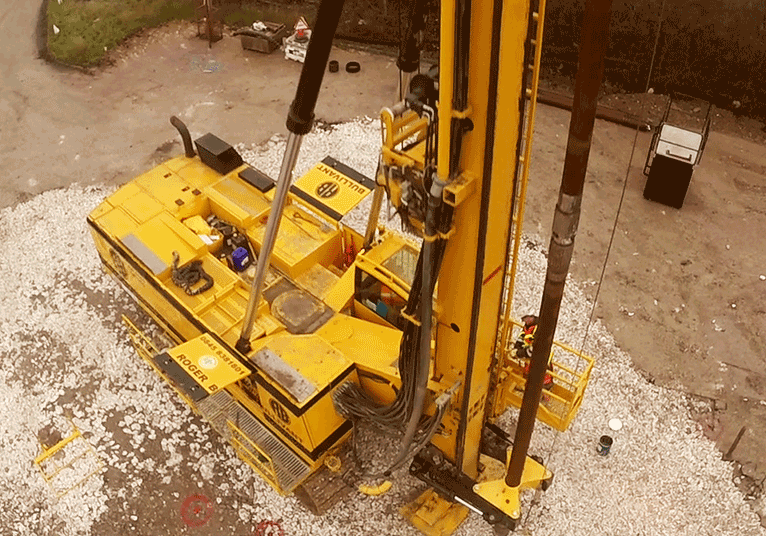

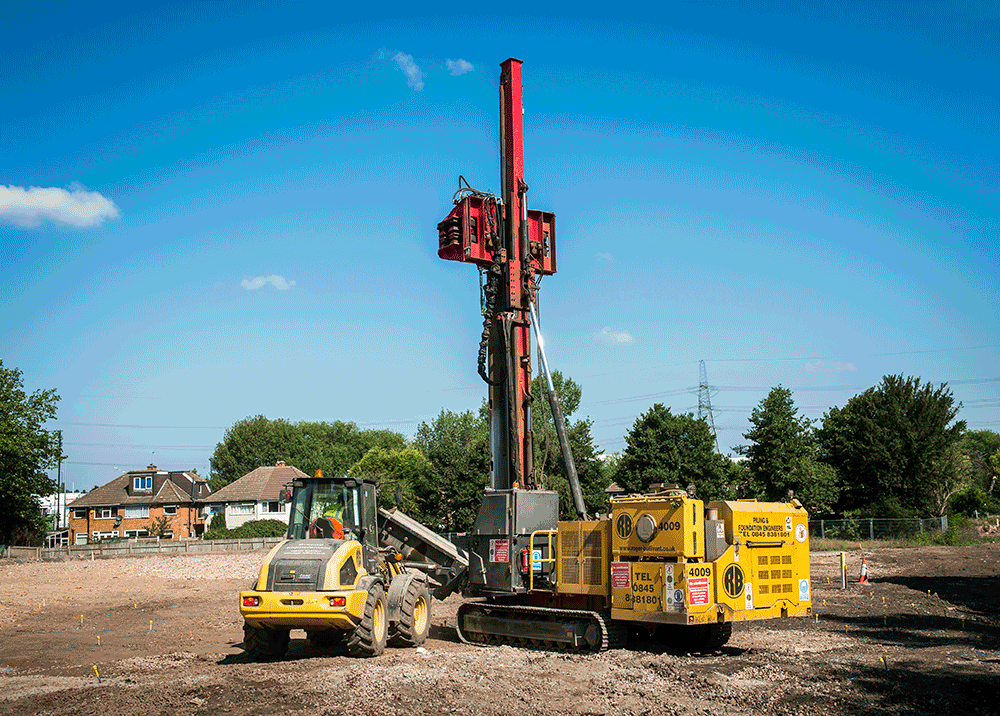

The installation process of Vibro Stone Columns involves a series of precise steps aimed at displacing and consolidating the soil to create a stable foundation. Initially, a specialised vibro piling rig is employed, equipped with a vibrating steel poker. This vibrating poker is strategically inserted into the ground to the predetermined depth, effectively displacing the soil and creating a void.

Once the desired depth is reached, the poker is carefully withdrawn, leaving behind a void within the soil. Subsequently, graded aggregate is poured into the hole and compacted in layers by reintroducing the vibrating poker. This forms the Vibro Stone Columns within the void, providing support and reinforcement to the surrounding soil.

To ensure optimal compaction and integration of the stone columns, the vibrating poker is re-inserted into the column bore. This action effectively compacts the stone aggregate, enhancing its density and solidifying its connection with the surrounding soil. By following this procedure, Vibro Stone Columns are effectively installed, providing a durable and reliable foundation solution for various construction projects.

BOTTOM FEED METHOD

The bottom feed system serves as an alternative to the top feed method, particularly in scenarios where the stability of the borehole is at risk of collapsing upon withdrawal of the vibro poker. This approach is commonly adopted when dealing with weaker soils prone to instability during the installation process.

In essence, the bottom feed system closely mirrors the top feed method, albeit with a crucial distinction in the placement of the aggregate. Instead of pouring the aggregate from the top of the borehole, as done in the top feed method, the aggregate is introduced into the bottom of the borehole directly from the surface. This is achieved through the implementation of a hollow poker, allowing for the controlled delivery of the aggregate to the desired depth within the borehole.

By introducing the aggregate from the bottom upwards, the bottom feed system minimises the risk of borehole collapse during installation, ensuring the stability and integrity of the surrounding soil. This method offers an effective solution for addressing the challenges posed by weaker soils, providing a reliable foundation reinforcement technique for various construction projects.

WHY USE Vibro Stone Columns?

- Zero spoil

- Can be used in a variety of soil and ground conditions

- In-house fleet of vibro stone column rigs

- More efficient and cost-effective

- Can offer top or bottom feed without the need to mobilise additional plant

- Quick installation

- Treatment depths up to 8m

EXAMPLE VIBRO STONE

COLUMNS PROJECTS

ROGER BULLIVANT

QUALITY CONTROL

We successfully deliver projects to the highest standard, safely, on time, within budget, and with care for the environment and communities. Clients choose RB time and time again thanks to our proven track record.

All products are manufactured to BSEN, ISO, and CE accreditation. We are committed to ensuring we continuously deliver high quality, robust service, and product to our clients. At RB we continuously review and access where we can further improve.

We are proud to be recognised and awarded the RoSPA gold award for the sixth year running for the exceptionally high standards towards the health and safety of our employees.