Jack Piles offer a specialised solution for underpinning applications, particularly in scenarios with limited access or space constraints or where noise needs to be kept to a minimum through their quiet and vibration-free operation.

This technique involves the insertion of piles into the ground to reach a stable bearing stratum, providing essential support and reinforcement for existing structures. What sets Jack Piles apart is their quiet and vibration-free operation, making them ideal for projects where minimising disturbance is paramount.

WHAT THEY’RE USED FOR

Jack Piles and Jack Pile Rafts are an ideal solution for projects involving sensitive structures, historic buildings, or locations where minimising disruption is crucial. Employing a quiet and vibration-free technique, these methods offer a gentle approach to foundation reinforcement, ensuring the preservation of delicate structures and minimising the risk of damage or disturbance.

Sensitive structures, including listed buildings or heritage sites, require special consideration during construction or renovation projects. By employing Jack Piles and Jack Pile Rafts, contractors can effectively reinforce foundations without compromising the integrity or aesthetics of these architectural treasures.

Furthermore, Jack Piles and Jack Pile Rafts are versatile solutions that can be applied to a variety of residential and commercial sites. Whether it's strengthening foundations for new construction, stabilising existing structures, or underpinning foundations to address settlement issues, these techniques offer a reliable and efficient approach that meets the needs of diverse projects.

THE PROCESS

The installation of a reinforced concrete (RC) raft within an existing building involves a process aimed at reinforcing the foundation and transferring structural loads to the underlying ground. This technique is particularly effective for strengthening existing structures and addressing foundation issues without the need for extensive excavation or disruption.

To begin the installation process, the RC raft is positioned within the building and needled into all load-bearing walls. Prior to pouring the concrete for the raft, tapered cones, and holding down (HD) bolts are strategically placed within the reinforcement at predetermined pile locations. These cones and bolts serve as guides and anchor points for the subsequent installation of jack piles.

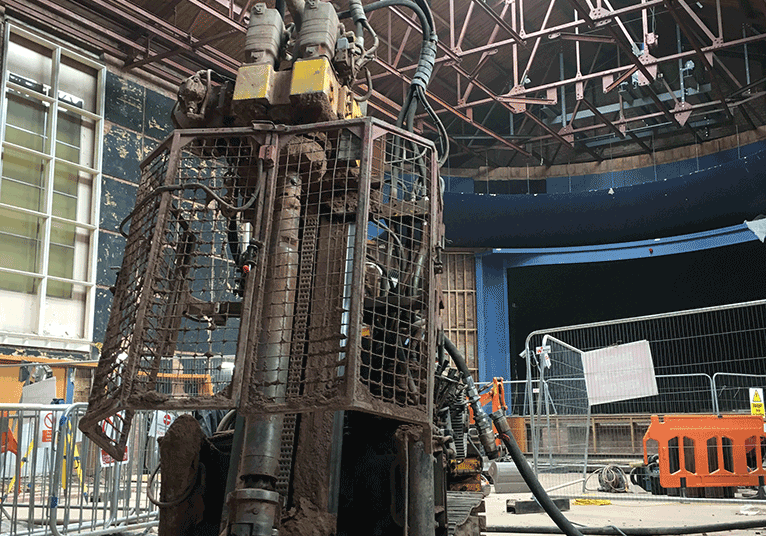

Once the concrete for the raft has cured, the tapered cones are removed, and the jack rig is positioned over the pile locations. The rig is securely fastened to the raft using the HD bolts, ensuring stability and alignment during the pile installation process.

Thick-walled steel tubes, typically measuring 1.5 meters in length, are then jacked down through the RC raft at each pile location. These steel tubes are interconnected using a spigot/socket arrangement, ensuring a secure and continuous connection as they descend through the raft. The jacking process continues until the desired design load is achieved, indicating that the piles are adequately supporting the structure.

Once the design load has been attained, the steel tubes are over-jacked to ensure that the top of each tube aligns with the underside of the raft. This ensures optimal load transfer and structural integrity. Finally, the voids around the steel tubes within the RC raft are filled with concrete, and steel reinforcement, to transfer the load transfer from the structure onto the individual piles.

WHY USE Jack Piles And Rafts?

- Generates no spoil

- Vibration free

- Quiet installation

- Quick installation

- Limited headroom & restricted access sites

- Utilises small, lightweight equipment

ROGER BULLIVANT

QUALITY CONTROL

We successfully deliver projects to the highest standard, safely, on time, within budget, and with care for the environment and communities. Clients choose RB time and time again thanks to our proven track record.

All products are manufactured to BSEN, ISO, and CE accreditation. We are committed to ensuring we continuously deliver high quality, robust service, and product to our clients. At RB we continuously review and access where we can further improve.

We are proud to be recognised and awarded the RoSPA gold award for the sixth year running for the exceptionally high standards towards the health and safety of our employees.