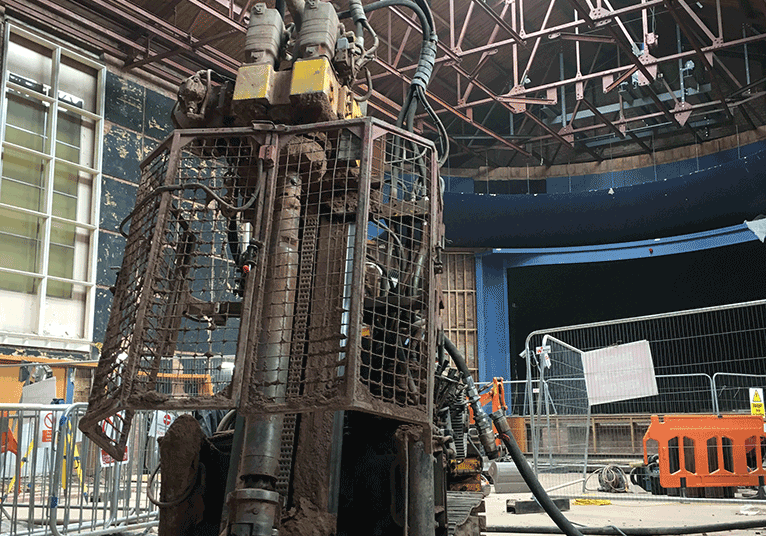

The Grundomat tool utilises hydraulic power to drive the pile into the ground from the bottom, providing a controlled and precise installation process. This method offers several advantages, including reduced noise and vibration levels, minimal disruption to the surrounding environment, and faster installation times compared to traditional piling methods.

Grundomat piles stand out as a popular choice in the domestic construction market, particularly for property extensions and underpinning projects. These piles, characterised by their bottom-driven steel tubular construction, offer a reliable and efficient solution for reinforcing foundations and supporting structural loads. What sets Grundomat piles apart is the tool used to drive them which eliminates the need for a traditional piling rig. This feature allows Grundomat piles to be installed in confined working areas and sites with heavily restricted access, making them an ideal solution for projects where space is limited, or access is particularly challenging.

WHAT THEY’RE USED FOR

Grundomat piles emerge as a versatile foundation solution applicable across both residential and infrastructure sectors, offering reliable support for various structures. While they are particularly well-suited for lightweight structures, Grundomat piles can also be deployed effectively in groups to accommodate higher pile cap loads, providing a robust foundation system for a wide range of construction projects.

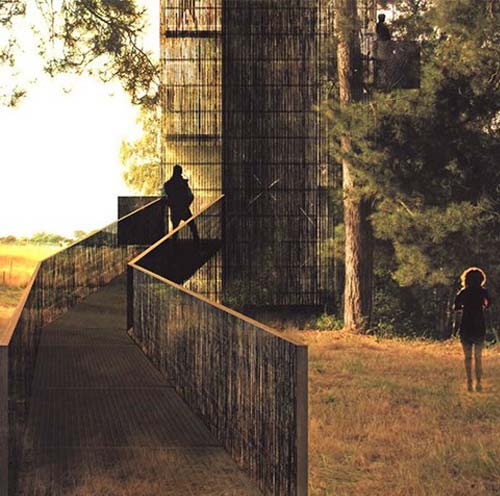

One of the key advantages of Grundomat piles is their ability to be installed using lightweight machinery, which results in minimal vibration during the construction process. This makes them an excellent choice for environmentally sensitive areas where minimising disturbance to the surrounding ecosystem is paramount. By employing lightweight equipment, contractors can mitigate the impact on nearby habitats, wildlife, and communities, ensuring responsible and sustainable construction practices.

In the residential sector, Grundomat piles are commonly used for property extensions, underpinning existing structures, and supporting lightweight buildings such as townhouses, and low-rise apartment complexes.

In the infrastructure sector, Grundomat piles find application in a variety of projects, including bridge abutments, retaining walls, noise barriers, and utility installations. Their versatility and adaptability allow engineers to tailor the foundation design to the specific requirements of each project, ensuring optimal performance and durability in diverse environments.

THE PROCESS

The installation process of Grundomat piles involves the use of specialised equipment and a systematic approach to ensure the stability and integrity of the foundation. It begins with the preparation of a starter casing, a closed-ended thin-wall steel tube, which is filled with a limestone or dry mix concrete plug. The Grundomat tool is inserted into the starter casing and connected to a compressor. This setup allows for controlled driving of the casing into the ground until it reaches the desired depth, with the top of the casing positioned just above ground level.

During the installation process, a follower casing, is welded onto the starter casing to extend the length of the pile and provide additional support. The installation is resumed, and additional casings are added as necessary to achieve the required depth or penetration rate. Once the pre-determined length or penetration resistance is achieved, the driving process is stopped, and the Grundomat tool is withdrawn from the pile.

With the Grundomat tool removed, the final pile configuration is assessed to ensure proper alignment and stability. The pile is then filled with either grout or concrete and reinforced to provide additional load capacity which enhances the piles performance and longevity.

WHY USE Grundomat?

- Minimal site preparation

- Minimum vibration

- Small lightweight equipment

- Limited headroom & restricted access

- Quick installation

- Zero spoil

ROGER BULLIVANT

QUALITY CONTROL

We successfully deliver projects to the highest standard, safely, on time, within budget, and with care for the environment and communities. Clients choose RB time and time again thanks to our proven track record.

All products are manufactured to BSEN, ISO, and CE accreditation. We are committed to ensuring we continuously deliver high quality, robust service, and product to our clients. At RB we continuously review and access where we can further improve.

We are proud to be recognised and awarded the RoSPA gold award for the sixth year running for the exceptionally high standards towards the health and safety of our employees.